At Chennai Forge Products, Quality is our watchword. We strongly believe in providing total customer satisfaction and we believe our success depends entirely in delivering excellent value to our customers. As an IATF 16949 certified organization our units adheres to strict quality standards right from the purchase of raw materials to the actual dispatch of components.

Our efforts are to exceed the standards expected by our customers and this is achieved by continuous improvement program in product and process development, building quality into the process and quick response to our customers.

Our objectives include developing our employees to improve and sustain their skills to meet the stringent quality standards of the organization. Acceptance Rate by the customers is of the order of 99% to 100%. We have been certified by Ashok Leyland Ltd., for achieving 100 PPM in finished components (Forging with Machining). Our components are exported to Cummins, USA through our customer TVS-Sundaram Fasteners, Ltd. Also our new components are exported to WABCO EUROPE through our customer LUCAS TVS, Chennai.

We have complete in-plant quality control and an inspection department to maintain high standards of precision and accuracy of forgings. Our Quality Assurance program is driven by:

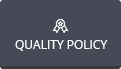

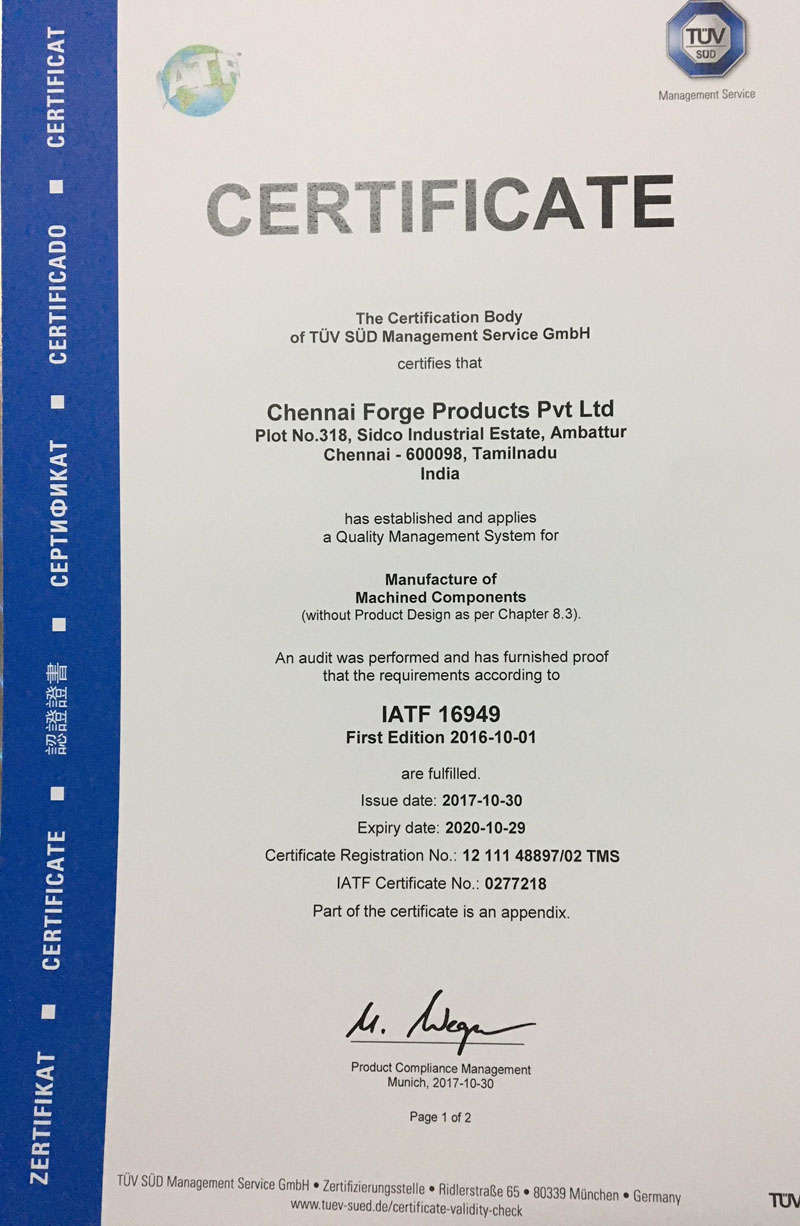

IATF 16949

Chennai Forge Products achieved the IATF 16949 certification by TUV-SUD in the year 2017.

Lean Six Sigma

Participated in 6 days training course on Lean Six Sigma organized by Ashok Leyland in July 2011. As a part of that initiative completed a Six Sigma Project using the tools and techniques learned in the training course.