The Company is a MSME Unit located in Plot No. New No. 57, (Old No.-67), SIDCO Industrial Estate, Ambattur, Chennai – 600 098, and was incorporated in the year 1975 as a Partnership Firm in the Name of FORGE PRODUCTS. This was changed in the year 2001 as Private Ltd. Company in the name and style of CHENNAI FORGE PRODUCTS PVT. LTD.

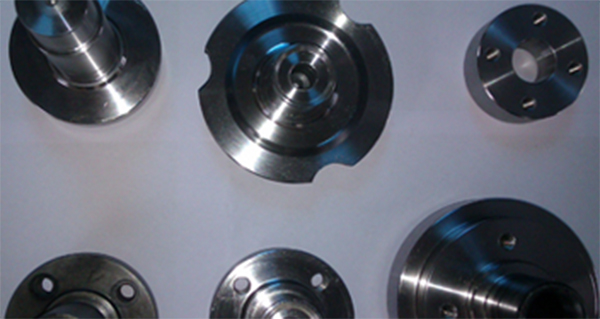

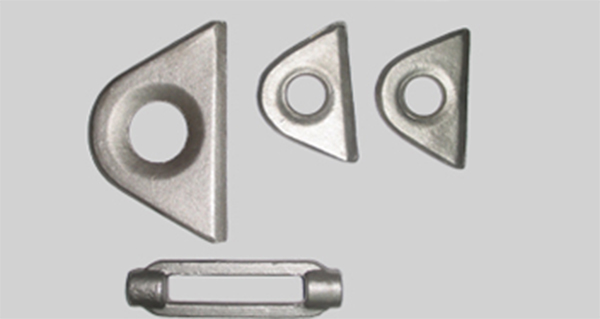

The unit has been planned to manufacture steel forgings and machined components for Automobile, Agricultural, Power, Earthmoving Equipments, Oil Sector and other Engineering Sectors. To mention a few, the unit produces Gear forgings, Rocker levers, Flanges, Jaw end, Eye end, Brake pedal pads, Cam bushes, small crank shafts and connecting rods, Levers of various descriptions, Sleeves etc. as per the requirements and specifications of the customers. The unit is capable of producing steel forgings ranging from 100 grams to 7 kilograms to cater to any end user.

We at present have Three Drop Hammers of 1.150 Ton, 0.750 Ton & 0.550 Ton capacity. We also have 200 ton Screw Press and 100 KW Induction Billet Heater. Our present forging capacity is of 2400 MT/annum.

The Unit adheres to strict quality standards right from the purchase of raw materials to the actual despatch of components. Acceptance Rate by the customers is of the order of 99% to 100%. We have been certified by Ashok Leyland Ltd., for achieving 100 PPM in Finished Components (Forging with Machining).

Vision

" Strive to achieve Forging excellence with ability to understand customer needs and deliver unsurpassed quality and reliable products to meet customer (domestic & global) demands, with total dedication and commitment from our staff. "

We have our own Tool Room catering to our Die making needs. The Tool Room has one BFW VMC, two Spark Erosion Machines, TOS Milling Machine & HMT Milling Machine, two Shaping Machines, one Lathe and one Drilling Machine.

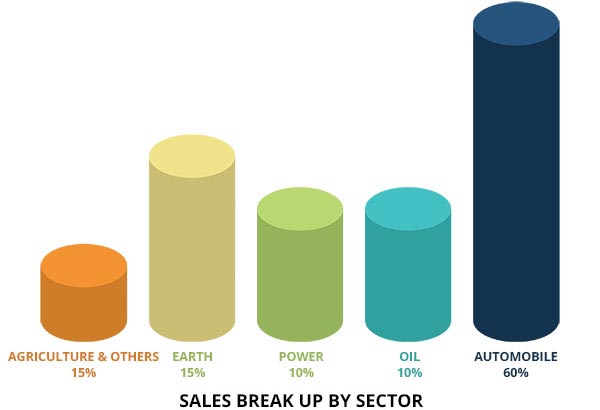

The company put up a separate Machine Shop Unit for supply of Finished Components (Machined). The unit has 27 CNC machines, 8 VMCs, 2 Cylindrical Grinding Machines, 3 Broaching Machines and other Conventional machines.

Chennai Forge Products Pvt. Ltd., had obtained ISO 9001 certification since the year 2003. In the year 2014, we completed the ISO/TS 16949: 2009 certification by TUV-SUD. In the year 2017, we achieved the IATF 16949 certification by TUV-SUD.